ألواح سيدنج للجبهة للبرغي المخفى MP-WH/S

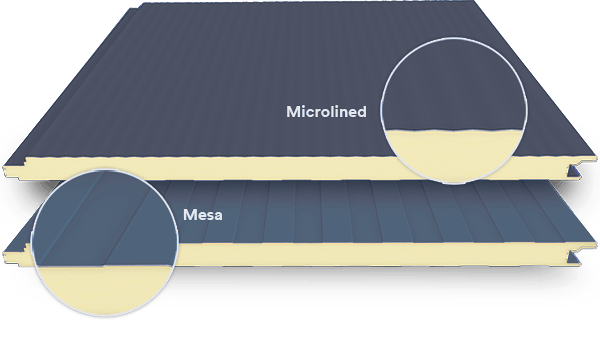

Surface of the panel can be produced as Mesa and Microlined texture. Panels can be montaged horizontally, vertically or angled and offers unlimited design possibilities with colour options to the designers.

| Insulation Material |

Fire Class |

Density |

Insulation Thickness (mm) |

Thermal Conductivity (λ) |

U Value | R Value |

|---|---|---|---|---|---|---|

| (W/m2K) | (h·ft²·°F/Btu) | |||||

| Polyisocyanurate (PIR) |

B s1 d0 (TS EN 13501-1) |

42 (±2)kg/m3 | 40 | 0.020 W/mK | 0,47 | 12 |

| 50 | 0,38 | 15 | ||||

| 60 | 0,32 | 18 | ||||

| 80 | 0,26 | 21 | ||||

| 100 | 0,21 | 27 | ||||

| 120 | 0,17 | 33 | ||||

| 150 | 0,14 | 42 | ||||

| 180 | 0,11 | 50 | ||||

| 200 | 0,10 | 56 | ||||

| External Sheet | Prepainted Galvanized Steel/Aluminium 0.35-0.40-0,45-0,50-0,60-0,70 mm | |||||

| Internal Sheet | Prepainted Galvanized Steel/Aluminium 0.30-0.35-0.40-0,45-0,50-0,60-0,70 mm | |||||

U value calculated due to TS EN 14509.U value converted to American R Value.

| Insulation Material |

Insulation Thickness (mm) |

External Steel (mm) |

Internal Steel (mm) |

Weight (kg/m2) |

Span Type (mm) |

Span Distance | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| 1000 | 1500 | 2000 | 2500 | 3000 | ||||||

| Max.Distributed Load (kg/m2) | ||||||||||

| Polyisocyanurate (PIR) |

40 | 0,50 | 0,40 | 9,44 | Two Span | 240 | 186 | 150 | 116 | x |

| Multi Span | 247 | 191 | 153 | 124 | x | |||||

| 50 | 0,50 | 0,40 | 9,86 | Two Span | 315 | 248 | 205 | 169 | 103 | |

| Multi Span | 322 | 255 | 210 | 175 | 105 | |||||

| 60 | 0,50 | 0,40 | 10,28 | Two Span | 390 | 311 | 263 | 223 | 130 | |

| Multi Span | 397 | 320 | 268 | 228 | 137 | |||||

| 80 | 0,50 | 0,40 | 11,12 | Two Span | 544 | 441 | 379 | 333 | 202 | |

| Multi Span | 551 | 452 | 392 | 339 | 213 | |||||

| 100 | 0,50 | 0,40 | 11,96 | Two Span | 696 | 574 | 495 | 444 | 290 | |

| Multi Span | 705 | 586 | 510 | 452 | 304 | |||||

| 120 | 0,50 | 0,40 | 12,80 | Two Span | 855 | 710 | 621 | 557 | 402 | |

| Multi Span | 861 | 720 | 634 | 568 | 411 | |||||

| 150 | 0,50 | 0,40 | 14,06 | Two Span | 1090 | 914 | 808 | 731 | 575 | |

| Multi Span | 1095 | 925 | 823 | 745 | 584 | |||||

| 180 | 0,50 | 0,40 | 15,32 | Two Span | 1325 | 1120 | 997 | 907 | 718 | |

| Multi Span | 130 | 1131 | 1012 | 924 | 731 | |||||

| 200 | 0,50 | 0,40 | 16,16 | Two Span | 1483 | 1258 | 1123 | 1026 | 804 | |

| Multi Span | 1485 | 1269 | 1139 | 1044 | 829 | |||||

Notes:

. Values have been calculated using the allowable “Stress Design” method, taking self weight, imposed loads (wind load) and temperature (Δt=±20ºC) into account.

. If loads are effected as downwards l/200 and l/150 , ıf loads are effected as suction l/150 deflection limits have been used

. Values have been calculated using the steel quality fγ=240 Mpa(Yield Strength).

. In Panel weight calculations, Polyurethane density is taken as 40 kg/m3 and Polyisocyanurate density is taken as 42 kg/m3.